Contact: Dolores (Mohr) Kenyon

E-mail: dolores@wiclarkcountyhistory.org

Surnames: Ackerman

----Source: Clark County Press (Neillsville, Clark Co., WI) 7/27/2022

O-W Maple Syrup Operation Highlighted at Farm Tech Days (2022)

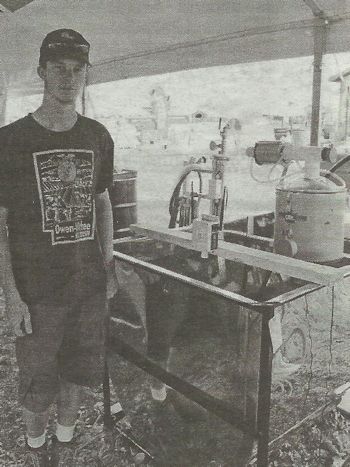

Elliot Ackerman shows a releaser used in the collection of maple sap. The knowledgeable Owen-Withee student explained the entire sap collecting process to visitors at Farm Tech Days.

Valorie Becht/Clark County Press photos

By Valorie Brecht

When people think of agriculture in Clark County, they often think of dairy or crop farming. Less often do they think of other products made in this area, such as maple syrup. For that reason, organizers of this year’s Innovation Square in Farm Tech Days decided to include a booth about a maple syrup operation that provides a learning experience for area youth.

Owen-Withee FFA members collect sap in the 80-acre school forest north of Owen. They don’t actually boil the sap in the forest; it is shipped to local maple syrup makers.

The students tap about 1,900 trees each year. It takes a roughly eight-person crew three days to tap all the trees. Each tree gets one tap. If the tree is wider than what one person can reach their arms around, it gets two taps. Sap from the taps travels through a food-grade tubing system. There are more than 10 miles of tubing, with nine lines all feeding into the main line. A vacuum is used to pull the sap out of the tree and gravity does the rest of the work. The lines are gravity fed and have a 0.04 slope.

Shown is the tubing system like what’s used in the Owen-Withee School Forest.

A vacuum is used to pull the sap out of the tree and the lines ae gravity fed.

“If it’s too flat, it doesn’t flow decently,” said Owen-Withee FFA member and high school senior Elliot Ackerman, who was stationed at Farm Tech Days booth.

The sap collects in a mechanical releaser. The mechanical action works off of floats and a vacuum, meaning that no electricity is required to run the releaser. After six gallons of sap fill the main canister, the float within the canister activates the vacuum piston that works the mechanism and allows the collected sap to be released into the storage tank.

“This way it pumps the sap all at once and it doesn’t have to run constantly,” said Ackerman.

The school forest property is sloped away from the road, so there is a separate pump that sends sap from the bottom of the hill to the top. The students collected 32,000 gallons of sap last year. The ratio is approximately 30 gallons of sap to one gallon of syrup, although the sugar content of the sap affects that, Ackerman explained.

Part of the sap collecting operation is a monitoring system that provides real-time data back in the classroom.

In addition to a mechanical releaser, the FFA students also had an electrical releaser on display at their booth as well as some other equipment from Roth Sugar Bush of Cadott, which is the largest CDL maple supplies and equipment dealer in the U.S.

Wisconsin’s maple syrup industry

Wisconsin is the fourth-largest producer of pure maple syrup in the U.S. This past spring, a record 440,000 gallons of syrup were produced in Wisconsin.